Robotic arms are at the core of modern production and manufacturing, are changing the rules in a way previously thought to be not possible. They are able to combine high-quality, safety and efficacy. Robots are amazing mechanical devices that have become essential in many industries around the world. They were developed to lower operating costs and keep up with the highest quality standards. In integrating robotic arms into production lines, manufacturers are not just reducing costs but also revolutionizing workplace safety and efficiency. Let’s see how these cutting-edge machines are transforming the industrial landscape.

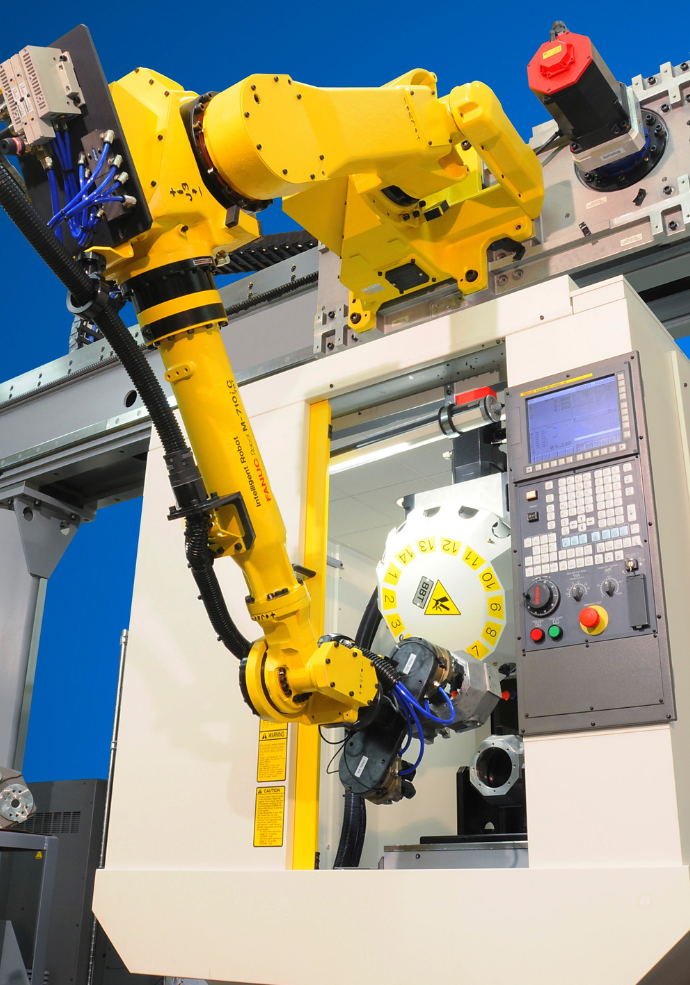

Image credit: automatedsolutions.com.au

The primary force behind the global surge in robotic arm adoption is cost efficiency. The demand on factories to decrease production errors, waste materials and workplace accidents are constant. Robotic arms were designed to solve these issues. In contrast to human workers, robotic arms complete repetitive tasks with pinpoint precision that eliminate costly errors and reducing raw material wastage. For high-volume industries, like automotive manufacturing, robot arms ensure an exact assembly process by using precise welding and part placement. This precision results in significant savings since fewer imperfections result in less waste, rework and work.

Security is another pillar of the robotic arm revolution. Certain manufacturing processes like handling dangerous materials or using heavy machinery could be hazardous for human workers. With the help of robot arms, companies can remove employees from these hazardous areas, greatly decreasing the risk of injuries sustained in the workplace. Robotic arms, which are designed as a kinematic ring of movable joints, mimics the functionality of a human arm but without the risk of physical harm. They are equipped with robotic hands, or programmable end-effectors. They can be used for tasks such as grasping, spinning and welding under conditions that would make it dangerous for human beings.

Robotic arms are an exciting development in diverse industries due to their adaptability. Robot arms are adaptable to various tasks. From assembly for automobiles to electronics production. The fact that they can be programmed allows them to execute complex tasks such as machine tool tending painting, painting, or fiberglass application, with unmatched consistency. Robotic arms used in warehousing has revolutionized palletizing by automating the load of goods onto pallets. Automation not only increases efficiency but also ensures safety as robot arms can be productive without fatigue.

Cobots are the latest breed of robots able to work in tandem with humans. Cobots that have robotic arms, in contrast to traditional industrial robots, which are isolated in cells, are specifically designed to be able to communicate with humans securely and efficiently. The robotic hand of a cobot can be used to perform heavy lifting and repetitive tasks in factories, meaning humans are freed to focus on more difficult duties. Collaboration increases efficiency and ensures a secure work environment, as cobots can be programmed to change or stop their movements when a person is near.

The effect of robotic arms extends far beyond safety and efficacy to the very fabric of modern manufacturing. They are indispensable to industries that require high precision in tasks such as welding, assembly or material handling. In the automotive industry for instance, a robot arm can move and position parts during assembly to ensure perfect alignment, without the requirement for human intervention. In electronics, robots are employed to manage delicate components, which reduces the risk of damage and enhances the quality of output.

As industries continue to evolve, robotic arms’ role will increase. The ability of robot arms to reduce cost, increase safety and adjust to different tasks make them the foundation of manufacturing’s future. By combining cutting-edge technology with human creativity robotic arms aren’t only tools, they are partners in advancement, bringing innovation to the forefront and transforming how we construct our world.